- Software Gestor para Aquicultura

- (85) 2139-6730

- contato@despesca.com.br

Fish Farming: How to Calculate Initial Investment and Break-Even Point

Aeration and Water Renewal: The Definitive Guide to Maximize Production and Reduce Costs

21/08/2025

Aquaculture Cold Chain: Ensuring Your Seafood’s Quality

25/08/2025Fish farming stands out as a high-potential activity in the agribusiness sector, driven by the high demand for fish and favorable national conditions. Success in this field, however, goes beyond cultivation techniques, requiring precise and detailed financial planning. The failure to correctly estimate costs and economic viability is one of the main causes of failure in new projects.

Two of the most important indicators for any aquaculture entrepreneur are the initial investment amount (CAPEX) and the operational break-even point. Mastering these calculations is the first step toward structuring a profitable and long-term operation.

1. Mapping the Initial Investment (CAPEX)

The initial investment includes all expenditures necessary to get the project fully operational before the first batch of animals is introduced. These costs can be categorized as follows:

- Infrastructure and Civil Works: This often represents the largest portion of the investment. It includes land acquisition or leasing, earthmoving services, and the construction of ponds, tanks, or the installation of net pens. Additionally, it covers water intake, supply, and drainage systems, as well as essential support structures like feed storage facilities, an office, and sanitary facilities.

- Machinery and Equipment: This covers the assets needed for daily farm operations. The list should include aerators, water pumps, equipment for water quality monitoring, such as oximeters and pH meters, feeders, nets for handling and harvesting, precision scales, and, depending on the project’s scale, transport vehicles.

- Initial Supplies and Legalization: This corresponds to the acquisition of the first batch of fingerlings, whose genetic and health standards are crucial for the cycle’s performance. An initial stock of feed and other zoosanitary supplies must also be provisioned. Legalization costs, such as company registration, environmental licensing, water use permits, and fees for technical experts, are also part of this group.

- Working Capital: This represents the financial reserve intended to cover operational costs during the first months of activity, a period before the first revenues are generated. The lack of adequately sized working capital compromises cash flow and the continuity of operations, making it a critical planning error.

2. Structure of Operating Expenses (OPEX)

Once the operation begins, the farm starts incurring production costs, which are divided into two types:

- Fixed Costs: Expenses that do not vary with the production volume. Examples include salaries for permanent staff, rent, insurance, depreciation of machinery and equipment, and general administrative expenses.

- Variable Costs: Costs that are directly proportional to the production volume. The main component is feed, which can account for up to 70% of the total cost. Other variable costs include the acquisition of fingerlings for subsequent cycles, electricity consumed by pumps and aerators, fuel, and labor hired for specific activities like harvesting.

3. Calculating the Break-Even Point

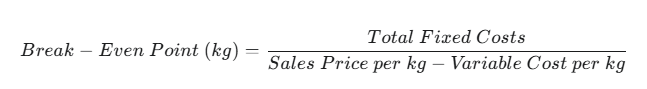

The Break-Even Point indicates the production volume (in kg) or revenue (in $) that a farm needs to achieve to cover all its fixed and variable costs. From this point on, the operation begins to generate profit. The formula for the calculation is:

The difference between the “Sales Price per kg” and the “Variable Cost per kg” is known as the unit Contribution Margin.

Practical Example:

- Annual Fixed Costs: $100,000.00

- Average Sales Price: $15.00/kg

- Unit Variable Cost: $9.00/kg

Calculation:

- Contribution Margin: $15.00 – $9.00 = $6.00/kg

- Break-Even Point (kg) = $100,000.00 / $6.00 = 16,667 kg

In the scenario above, the farm needs to sell 16,667 kg of fish per year to cover its costs. The break-even point in revenue would be 16,667 kg * $15.00/kg = $250,005.00.

The Role of Management in Financial Control

Pre-operational calculations are projections. Efficient management requires the continuous monitoring of these indicators with real data collected throughout the production cycles. Technology plays a fundamental role in this process.

The use of aquaculture management software, such as Despesca, allows for the detailed recording and analysis of all costs, associating them with specific ponds, batches, or cycles. The platform automates the calculation of the unit production cost, profit margins, and provides financial reports that compare the planned versus the actual results.

Precise control over costs and knowledge of the break-even point are indispensable tools for making strategic decisions, including pricing, planning expansions, and optimizing the business’s profitability.