- Software Gestor para Aquicultura

- (85) 2139-6730

- contato@despesca.com.br

The Hidden Cost of Feed: Calculating Feed Conversion Ratio and Profit Impact

10 Water Quality Parameters in Tilapia Farming: Technical Guide

24/12/2025In modern aquaculture, whether in fish or shrimp farming, efficiency isn’t just a competitive advantage; it’s a matter of financial survival. It is widely known that feeding represents between 60% to 70% of total production costs. However, many producers still neglect rigorous monitoring of the Feed Conversion Ratio, allowing hidden costs to silently erode the profit margin of each cycle.

Understanding the mathematics behind feed consumption and how external factors influence this number is the first step toward transforming a productive farm into a highly profitable business.

What is Feed Conversion Ratio and How to Calculate It

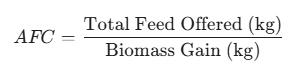

In technical terms, the Feed Conversion Ratio (FCR) is the index that measures the efficiency with which the animal transforms consumed feed into biomass (body weight). The lower this number, the more efficient the production. There are two main ways to analyze this indicator: Apparent Feed Conversion (AFC) and Economic Feed Conversion (EFC).

The basic calculation for AFC is performed using the following formula:

For instance, if a pond consumed 1,500 kg of feed to produce 1,000 kg of fish, the Feed Conversion Ratio is 1.5. This means 1.5 kg of feed were needed to produce 1 kg of protein. Although it seems simple, the “hidden cost” lies in variables not accounted for in this simple math, such as unobserved mortality and wasted feed settling at the pond bottom, harming water quality.

In this context, the use of Feed Conversion Ratio reference charts, provided by feed manufacturers or research institutions, becomes an essential benchmarking tool. These charts indicate the expected performance (the “target”) for each growth phase of the animal and water temperature. Comparing the result calculated on the farm against these standardized indices allows the producer to identify if the nutritional management is efficient or if there is a significant deviation—such as overfeeding—that requires immediate correction in feeding rates.

The Invisible Profit Thieves

The real impact on profit occurs when the Feed Conversion Ratio rises without the producer immediately perceiving the cause. Studies by Embrapa and recent scientific articles indicate that environmental factors are the main villains. When dissolved oxygen levels drop below 3.0 mg/L, for example, feed consumption might continue, but the animal’s metabolism slows down, resulting in zero growth and wasted inputs.

Furthermore, the lack of standardization in feed supply and the use of feeds with low digestibility levels increase the organic matter load. This forces the aeration system to work harder, also raising electricity costs—another hidden cost directly linked to poor feed management.

The Importance of Data Monitoring

To prevent feed from becoming a financial loss, it is fundamental to register water quality parameters daily and relate them to the batch’s consumption. Simple visual observation is insufficient to detect subtle deviations in the Feed Conversion Ratio which, accumulated over months, represent tons of wasted feed.

We recommend reading complementary content on water quality monitoring and sanitary management, available in the Despesca articles section, to understand how the environment directly impacts nutrition.

The Role of Technology in Efficient Management

Calculating feed efficiency manually, pond by pond, and comparing it with complex charts is a task prone to errors and consumes valuable time. This is where utilizing specialized management software, such as Despesca, becomes a game-changer.

By using the Despesca system, the Feed Conversion Ratio calculation is automated and compared with established goals. The producer enters feeding data and periodic biometrics, and the software instantly crosses this information, generating performance graphs and standard deviation alerts. This allows for:

- Quick Adjustment: Correcting the amount of feed offered before waste becomes significant.

- Traceability: Knowing exactly which batch, feed, or supplier is delivering the best economic result.

- Inventory Control: Avoiding stockouts or emergency purchases at elevated prices.

Conclusion

The cost of feed goes far beyond the price per kilogram paid to the supplier. It involves the animal’s biological efficiency, the quality of the culture environment, and the precision of management in following reference charts. Reducing the Feed Conversion Ratio by just a few tenths can mean a substantial increase in net profit at the end of the harvest.

Technology is the modern producer’s greatest ally. Adopting tools that transform raw data into business intelligence is no longer a luxury, but a necessity for those who wish to grow sustainably and profitably in aquaculture.